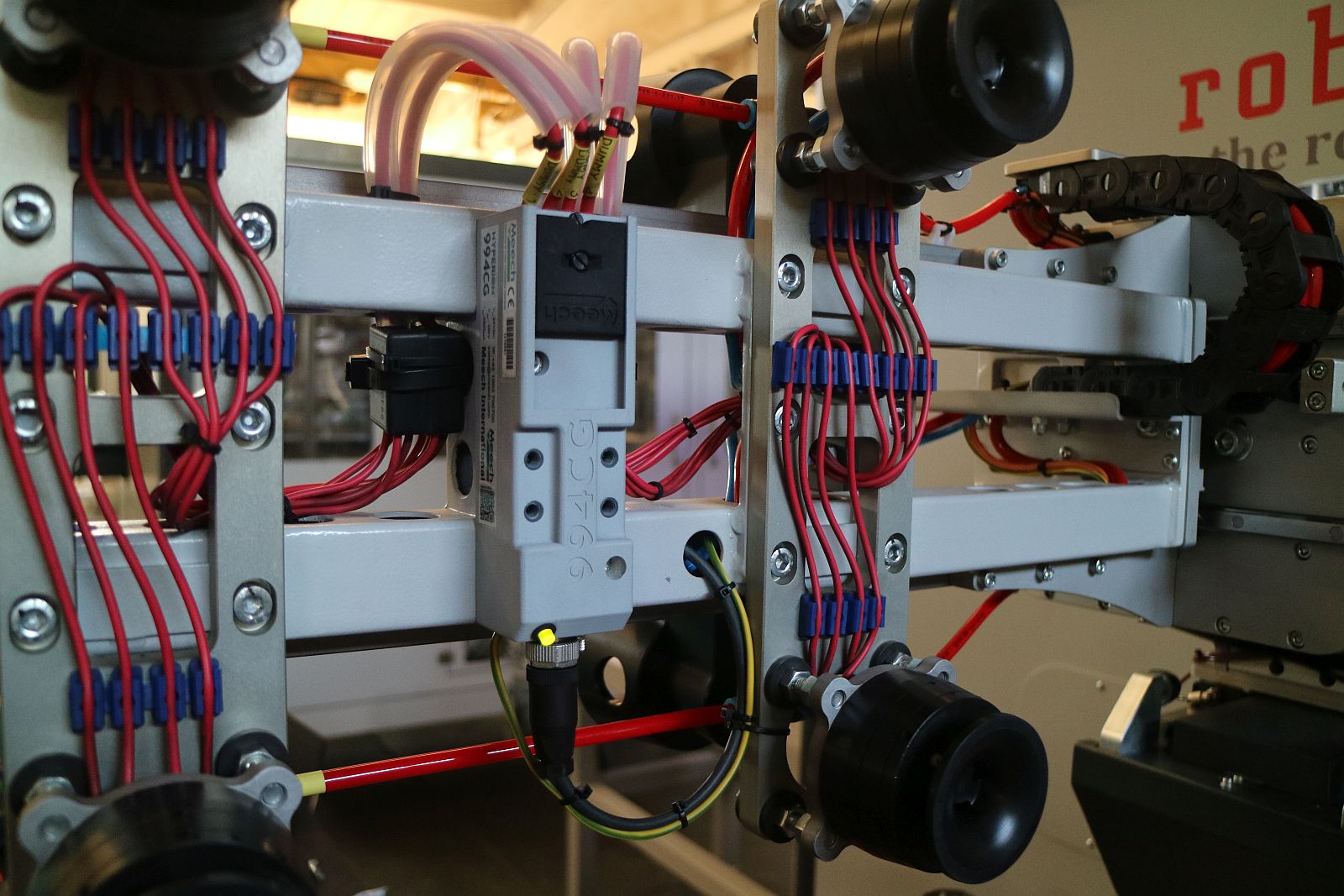

Turkish automation company Enelkon is an expert in the provision of high-tech solutions for the plastics packaging industry. Established in 2004, the company supplies its varied product range to a highly valued clientel who are based in 25 countries across the globe. Priding itself on the delivery of high quality, long-life automation solutions via its expert technical team and carefully chosen suppliers, Enelkon specialises in the development of IML (in-mould labelling) robotics. For the IML solutions that attach to the robots, the business relies on Meech’s static generation technologies, which include the 994CG Generator, 994CG Remote Setpoint Controller and 994 Hydra pinning system.

First installed in 2017, Meech’s technology took the place of Enelkon’s previous IML supplier equipment, which did not reach the Istanbul-based company’s high standard of operation: “Our previous provider’s equipment suffered a few difficulties, including technical failure, which had the potential to negatively affect our relationships with customers.” says Neslihan Özercan, Operations Manager at Enelkon. “What’s more, when faults occurred, the feedback from the supplier didn’t contain enough technical information on how the problems came about, or how the system could be improved to prevent these problems happening in the future.

“We decided to look for a new and more reliable IML solution – that’s when Meech’s representative in Turkey contacted us. Following a meeting to learn about Meech’s product offering, we didn’t hesitate to undertake a trial with its 994 IML technology. After seeing some impressive results, we were keen to implement the technology into our automation equipment. In fact, we also changed the design of our robots, mandrels and our static components to fully accommodate the Meech IML system.

“At Enelkon, we are determined to work with companies that provide innovative technologies and offer knowledgeable technical support. Meech cover these areas and we’ve been impressed by both their products and the team themselves.”

Özercan believes Meech’s 994 IML solution befits an evolving industry: “The latest trends in packaging are seeing more compact and flexible components making ground in the market – Meech’s 994 IML equipment, which is beyond any other static technology we’ve seen, goes hand in hand with these developments.

“For the best possible performance of our robots, it’s essential that our supplier offers experience, quality and reliability, while also offering an excellent after sales service. Meech ticks all these boxes. Since our investment in their 994 IML equipment, we’ve not experienced any product failures and we’ve noticed that our overall cycle time has decreased, total production has increased and wastage has dropped dramatically due to static failures being reduced to a minimum. We’ve also had more consistent overall performance compared to what a resin or static sponge solution would offer.”

Enelkon’s customers have been just as impressed: “Our customers are very satisfied with their end products,” Özercan continues. In fact, we’ve even received requests from some existing clients to have their current static systems changed over to Meech’s solutions and those that have made the change have already seen improvements in their production.”

As far as Özercan is concerned, the partnership looks set to continue for years to come: “Meech’s technical experience and knowledge has greatly impressed us. In the beginning, when we were learning to use the system, they were always on hand with advice and helped us develop an understanding of the equipment and how to get the best use out of it. They have also been happy to give our customers advice directly, to share their expertise and help them improve their practices.

“We’ve found Meech to be a fantastic partner for our business. Their professional, energetic and experienced team is a pleasure to work with and we are excited about what the future holds with them as a partner, as we continuously look to develop and improve our IML system offering.”

Stewart Gordon-Smith, Business Development Manager at Meech Static Eliminators says: “When Enelkon came to us looking for help, we knew our 994 IML equipment would be an ideal solution. They hadn’t received the adequate assistance from their previous supplier and needed a company that could not only provide an IML solution that was flexible, adaptable and capable of improving production, but also came with an experienced team that could guide them on how to get the best out of the equipment. We were pleased to provide the technology and expertise they required.

“It’s been a successful year working alongside Enelkon and we at Meech are excited to see what the future will bring as we continue to work together.”