It takes something special to surprise the judging panel at the Miraclon-sponsored Global Flexo Innovation Awards (GFIA), but that’s exactly what the joint entry from Fathom Optics and Grace Label achieved. So much so, that they even won a Gold Award (with Highest Honors) for conversion to flexo, commitment to sustainable print and creative use of graphic design.

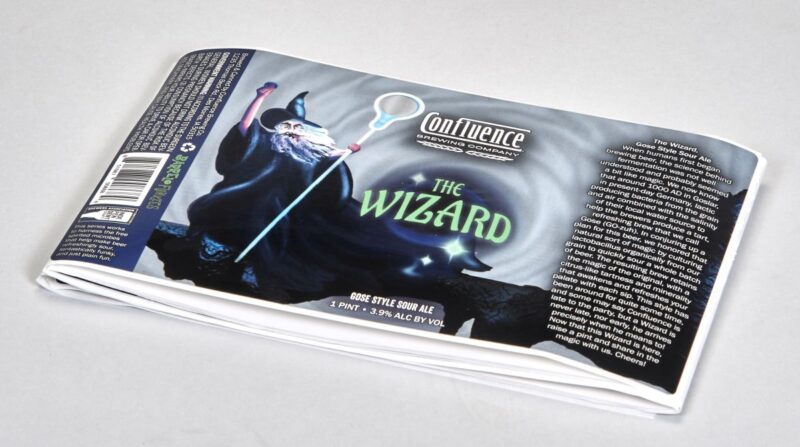

In what the judges described as “a really impressive innovation,” the label for Des Moines, Iowa, craft beer producer, Confluence Brewery, used Fathom’s brand-new embellishment technology to render attention-grabbing full-motion 3D effects on labeling for the brewery’s ‘Wizard’ Gose-style sour ale. The effects appear to be on three different levels: text and graphics on the label surface, a ‘Northern Lights’-type effect seemingly moving within the can itself, and finally, at the top of the wizard’s staff, a rotating orb that appears to emerge from the surface of the label.

And what made the job remarkable was the fact that all this was done without the need for lenticular lenses or a holographic foil, using FLEXCEL NX Plates on Grace Label’s standard flexo press using standard inks. Traditionally, the use of holographic foils or lenticular lenses for short label print runs has been cost-prohibitive, while holographic foils also raise sustainability concerns since they are typically 95% waste. FLEXCEL NX Technology makes special effects labels a viable option for brands pushing the boundaries of regular packaging designs for shorter runs, with big cost and sustainability benefits that they can take advantage of.

A strong-rooted relationship

Fathom Optics and Grace Label teamed up for the ‘Wizard’ label, which came about because of a friendship between the family of Tom Baran, CEO and Co-Founder of Fathom, and John Martin, owner/founder of Confluence, to whom Grace Label is an established label supplier. Founded in the mid-1970s by the father of current company president, Steve Grace, Grace Label is one of the oldest and largest regional converters in the Midwest US, operating as a full-service supplier that handles every step of the design-to-delivery process. Besides the craft beer and spirits industries, Grace also serves customers in meat and agricultural foods. The company has both digital and flexo presses, with flexo printing representing 90% of its work.

FLEXCEL NX Technology “like getting a brand-new press”

Crucial to the success of the ‘Wizard’ project was the KODAK FLEXCEL NX System, which Grace Label installed in 2011. “With the ability to hold a dot and sharpen an image, it was like getting a brand-new press on some levels,” recalls Steve Grace. “The plates last longer, we set up faster, dial in color faster, and reduce our wastage. It’s been a home run.”

Steve’s enthusiasm for FLEXCEL NX Technology was shared by Fathom Optics founders Tom Baran and Matt Hirsch: “When we realized Grace was a FLEXCEL NX Plate user we were delighted,” says Tom. “We’d already experienced good things with the technology, getting incredibly regular and consistent results. Compared to other systems we’ve worked with where variables come into play, it’s one cohesive system, so you know what you’re going to get.”

A fourth party to the project is creative design agency 818 Iowa, who created the original design and worked with Confluence to enhance the labels’ most characteristic features — the wizard, staff and orb. Fathom then worked with Grace to bring everything to life.

The effects are achieved by printing very fine microstructures on two interference screens. The first screen is printed on the white BOPP pressure-sensitive material, and the second screen is printed along with the other decorative inks on top of the clear lamination.

Because the microstructures are done at a minimum of 480 LPI or higher, the 1:1 pixel-for-pixel accuracy of the FLEXCEL NX Plates was essential to hold lines that are 10 microns wide and spaced approximately 42 microns apart. Says Tom: “These demanding effects can be incorporated into the same plate with the traditional 2D graphics, which may be at 133-175 LPI, without difficulty. It sounds highly challenging, but so far, every UV flexo printer we’ve worked with has been able to achieve some level of effects.”

Fierce competition for consumers’ attention

In the craft beer business, competition for shelf space and consumers’ attention is fierce, so imaginative, impactful labelling is hugely important for a small, independent brewery such as Confluence. In the case of the award-winning label, the ‘Wizard’ branding of the Gose-style sour ale opened all sorts of creative possibilities, with the favored option a multi-dimensional, moving 3D image that would capture shoppers’ attention as they walk by, and further engage them as they pick up the can and rotate to explore the image further.

Traditionally, such an effect is achieved using either holographic foils or lenticular lenses, but the short label print runs made both too expensive. In addition, there are sustainability concerns with holographic foils since they are typically 95% waste, while the lenticular approach presented the further complication of the lens orientation being incompatible with the direction in which the labels are applied to the can.

The answer lies in the East

Confluence didn’t know it at the time, but the answer lay 1,300 miles to the east in Somerville, a suburb of Boston, where the Fathom Optics founders, Tom and Matt, were marketing their groundbreaking new approach to embellishment, Fathom Effects. The technology came out of the partners’ PhD work at the Massachusetts Institute of Technology.

“The idea behind Fathom Effects is software-based, not materials science-based,” explains Tom. “The foundation of it is to take large-scale computational algorithms and use them to change the way materials interact with light. We compute complex interference patterns that can be printed on the front and back surfaces of film. They’re not interference patterns, like in holograms, but signal interference, as in moiré.”

If the technology behind Fathom is relatively complex, for end users adding special effects it is remarkably straightforward. Designers simply drop files into Fathom Designer, a free online tool, where they assign motion and depth effects which can be previewed and shared with other stakeholders.

After two years making the technology robust enough for long flexo runs, Tom and Matt settled on primary labels, shrink sleeves and product authentication as their primary markets. Says Matt: “We realized there are brands wanting totally custom packaging appeal but for whom the traditional holographic and lenticular solutions are too expensive. We differ in that we deliver 1-bit TIFF files to production sites — unlike holographic foil, where if you want a customized design, you have to order a truckload of film. On shrink sleeves, for example, with Fathom Effects there’s no additional cost — you’re just printing both sides of the film.”

He adds, however, that Fathom Effects is also gaining traction with larger brands, simply because it’s a software-based technology. “Large multinational consumer product groups often don’t want to get into new things because the qualification process for new material can take months, even years. But because our technology uses the same substrates, inks and flexo presses, no qualification process is required, and they can get to market faster. And, as we’re not adding a dissimilar material, like a lenticular lens or a hologram, there’s a sustainability advantage because recycling or reuse is easier. All these factors add a whole new level of acceptance.”

Coming soon to an aisle near you…

With Fathom Effects technology now onboarded at over 40 production sites, and strong interest from brands both large and small, 3D effects will be coming to more and more supermarket aisles before long. In part, this is due to winning the Award, says Tom, which has given a level of exposure that would otherwise have been hard to achieve: “With an innovation like ours, it can be difficult to talk about actual jobs due to confidentiality issues, although winning at the GFIA increased awareness. The award has significantly raised our profile, generating real business and — just as important — kickstarted relationships with some big-name brands. So, stay tuned for future announcements!”