Meech Static Eliminators will be presenting its new Hyperion SmartControl at Fachpack 2018 (Hall 4 stand 413, Exhibition Centre Nuremberg, 25th – 27th September 2018). The SmartControl provides advanced supervision of the Meech Hyperion range of static control devices which will also be exhibited at the show, alongside a comprehensive range of static generation equipment and web cleaning solutions.

Ralph Simon, Sales Manager at Meech says: “We’re delighted to be attending Fachpack once again. With representatives from such a range of various sectors attending this show, Fachpack provides us with the perfect platform to display our latest innovations in static removal, static generation and web cleaning – including the newest addition to our Hyperion product range, SmartControl.”

Providing ease of communication between connected Hyperion devices, the SmartControl offers remote adjustment of up to six devices through a single interface. Connected Meech Hyperion equipment can be adjusted quickly and remotely, via either a LAN or WAN network, reducing the need to monitor individual static control issues on site. One device is needed for the central control of up to six Hyperion products, with expansion kits available where more devices are needed to be monitored.

“SmartControl is Meech’s latest addition to the automation industry,” continues Simon. “It’s been developed, as with all our products, in line with customer feedback and our determination to provide the most appropriate solutions to help them be as productive as possible.

“Operators of Hyperion equipment will be able to access performance information through SmartControl and adjust the operating settings to achieve maximum productivity and quality output.”

Meech’s Hyperion bars, 924IPS, 929IPS and 971IPS, will be connected to a SmartControl on the stand, providing visitors a visual representation of how the device works. Offering long-range and mid-range ionisation respectively, the 971IPS and 929IPS bars deliver extremely powerful static control, while the 924IPS is one of the most compact pulsed ionising bars on the market. With quick and easy installation for use on converting lines, the Hyperion range provides industry leading static elimination.

Offering reliable static control solutions in the most hazardous environments, Meech’s 924EX is a compact pulsed DC ionising bar for use in the most challenging situations. It will be connected to the 233v4 – Meech’s most powerful pulsed DC controller for the anti-static Hyperion range. Suitable for use in a wide variety of sectors, the 233v4 is a compact and powerful device that enables greater control of the ionisation performance of up to two Meech pulsed DC ionisers. Offering ultimate flexibility and a maximum output voltage of 15kV, the 233v4 is suitable to use in a range of applications.

For the in-mould labelling market, Meech will be demonstrating the capabilities of its 994 Hydra miniature IML pinning system. Compact and lightweight, the system is devised for applications where size and weight are restricted. It will be connected up with the Hyperion 994CG – a compact generator that Meech designed to meet the growing demand for a smaller, lightweight generator that could fit on the end of a robot arm.

Both Meech’s 924EX and 994 Hydra will be connected to Meech’s Hyperion BarMaster Remote Programmer. This device temporarily connects in line with individual pieces of static control equipment, where adjustments to the output and clean pin alert settings can be made.

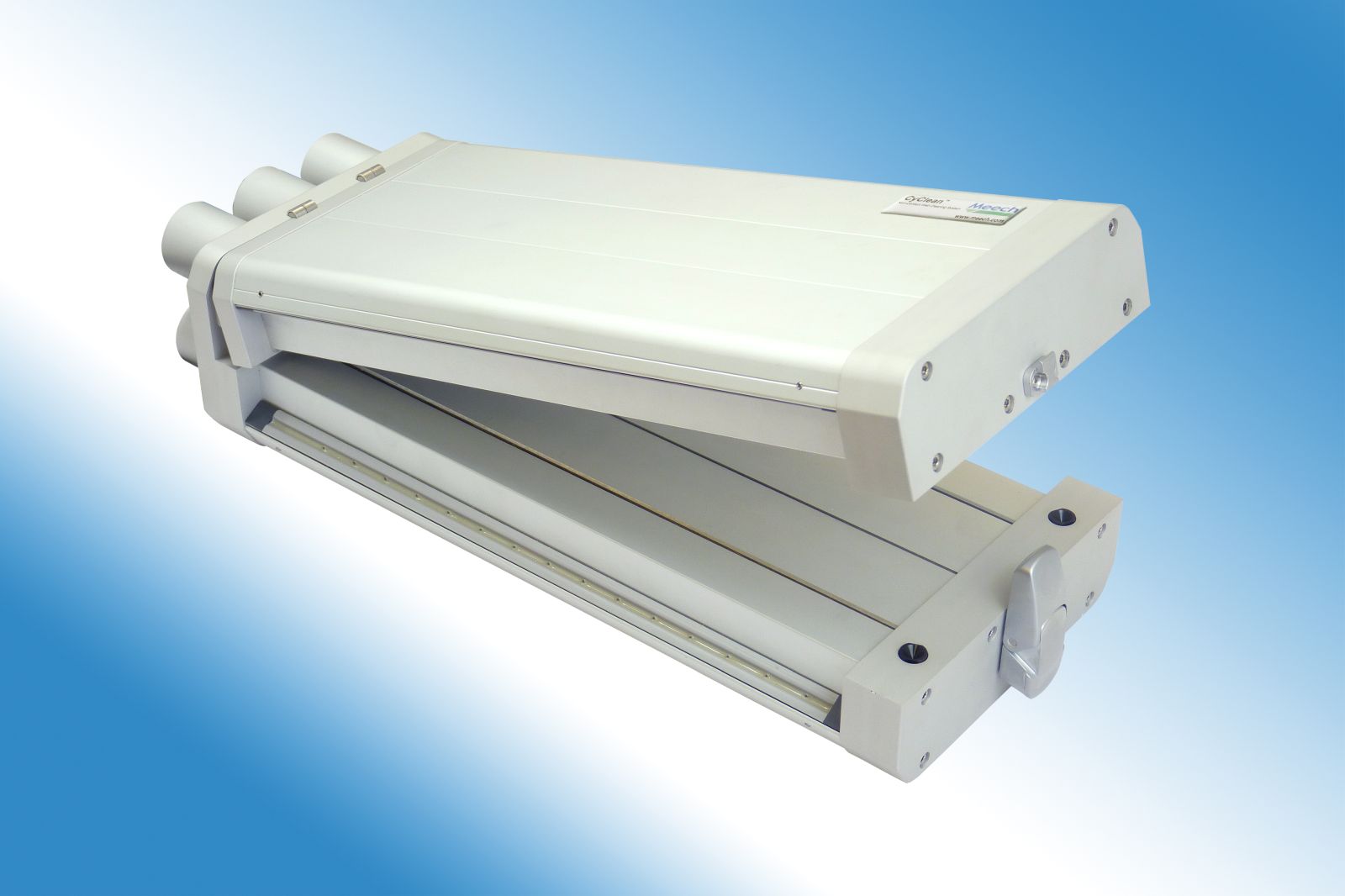

On display alongside the Hyperion product range is Meech’s complete set of web cleaning systems, including the CycleanTMand TakCleanTM. The CyClean™, a compact non-contact system with optimised cleaning efficiency, is capable of removing contamination to below 1 micron. Best suited for high speed presses, the CyCleanTM, can handle virtually any substrate, providing a future proof solution to the labelling industry. A contact web cleaner employed within the label printing sector, the TakClean™ features specifically formulated TransTak elastomer contact cleaning rollers and perforated adhesive rolls, which make it ideal for narrower and slower presses.

Simon concludes: “Fachpack provides us with a platform to demonstrate to an international audience why Meech has developed such a formidable reputation in the labelling sector. We look forward to welcoming visitors to our stand throughout the course of the show.”