Fewer hot topics have been bandied about trade shows more than ‘Industry 4.0’. And yet, despite the term being used to announce the arrival of a new industrial revolution, not many industry bods are familiar with its meaning, or more importantly, what it means for their business.

So let’s step back and look beyond the buzzword. In order to understand Industry 4.0, we must first understand the Internet of Things (IoT). The IoT is a network of physical objects embedded with internet-connected technology to communicate and cooperate both with each other and with humans in real time, via the cloud. The IoT is incorporated into a range of consumer devices, many of which fit smoothly into the patterns of our domestic lives, such as smart door locks, irrigation systems, energy monitors and even kitchens.

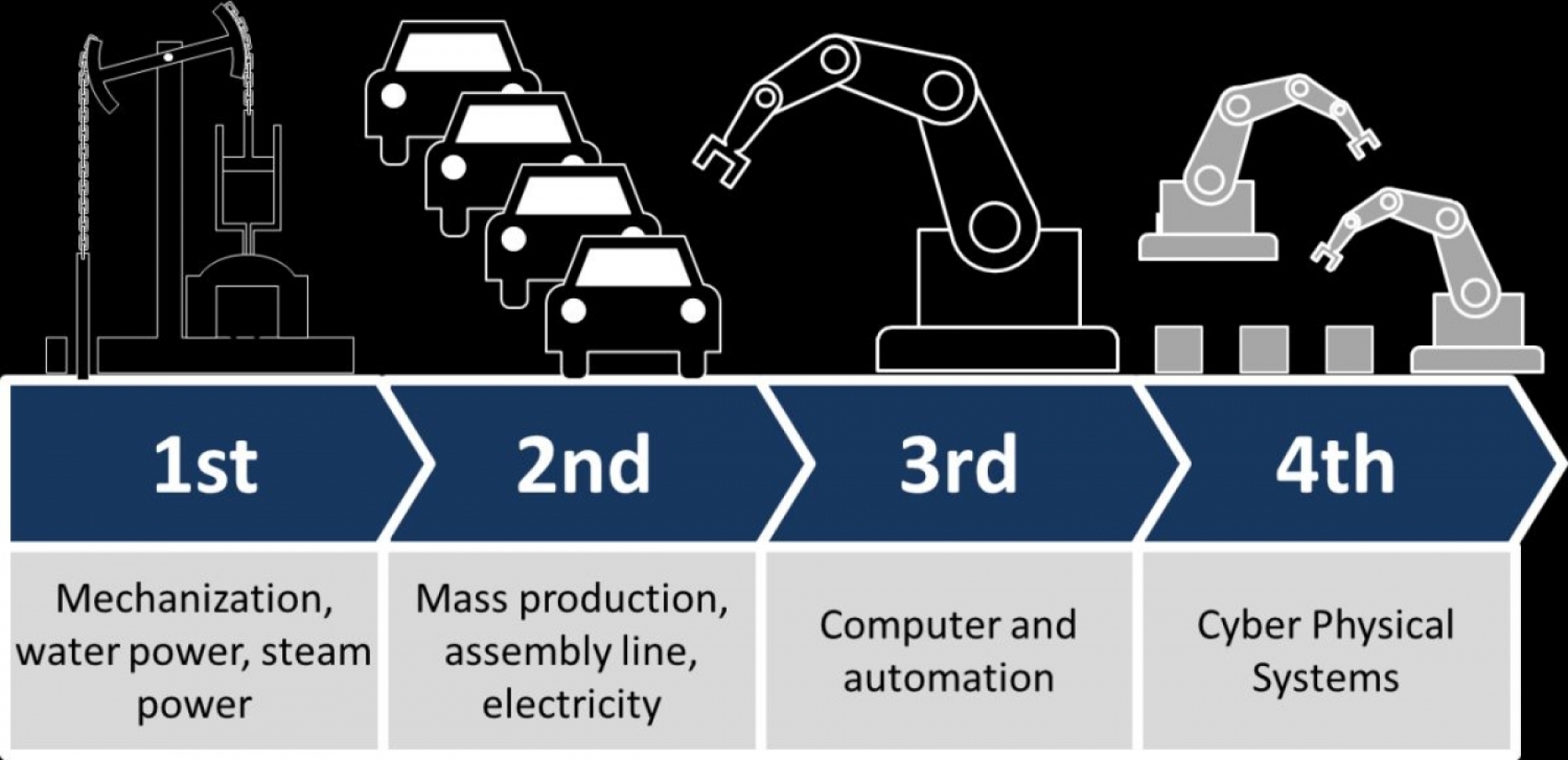

Industry 4.0 takes IoT into the factory environment and to the next level. As explained by Forbes, Industry 4.0 sees computers and automation seamlessly integrate with one another in an entirely new way, with robotics connected remotely to computer systems equipped with machine learning algorithms that can learn and control the robotics with little to no input from human operators. In short, Industry 4.0 introduces the concept of the ‘smart factory’.

But what does this mean for businesses? Maximum efficiency is the short answer. Such an unprecedented level of connectivity would result in the elimination of operator errors, while also allowing information to be captured at every point on the production process, anywhere on the supply chain. The resulting OEE data can then be analysed and managed to make every manufacturing sequence as swift and accurate as possible. Furthermore, the integration of monitoring systems means the smart factory will be constantly aware of the state, history, configurations, etc. of its equipment.

As with any major innovation, there are some apprehensions surrounding the introduction of a smart factory environment. IT and data security are obviously pressing issues, as is the potential loss of paying operator jobs, always a concern when new automations are introduced. Or perhaps the notion of relinquishing control and management of a factory to what is essentially an intangible entity still represents too big a leap of faith to some business owners.

Nevertheless, what remains undeniable is that the benefits and possibilities of Industry 4.0 outweigh the concerns surrounding this exciting technology. Industries around the world are eager to embrace the new industrial revolution and Interpack 2017, the world’s biggest packaging trade show, is the perfect place to learn more about this fascinating subject.

We’ll see you at the show!