Fujifilm Graphic Systems (Europe) today announces that its respected XMF Workflow portfolio has become fully integrated with Tharstern MIS (Management Information System) and EFI Pace MIS. These integrations enable a more streamlined print production process and will offer print providers enhanced productivity and lower costs.

With margins continually under pressure, printers are always looking for ways to increase automation and reduce labour costs. Done right, this has the added effect of streamlining the print production process, reducing turn-around times, ensuring more timely communication of job status to clients and providing more accurate measurement of job production costs to name just a few. Fujifilm’s XMF Workflow solution has been providing these benefits to customers for years and its integration with two of the leading MIS systems on the market now takes this to another level.

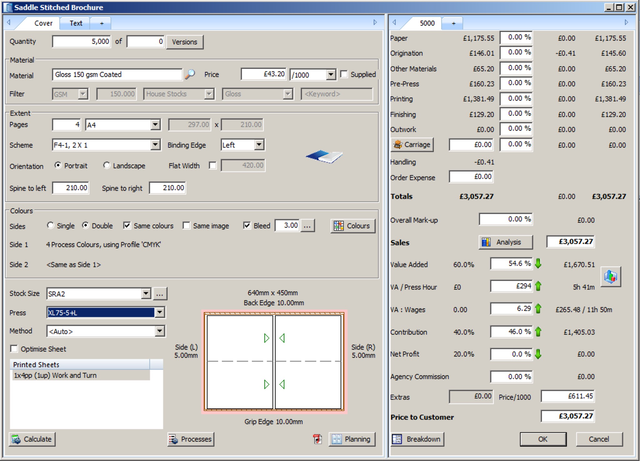

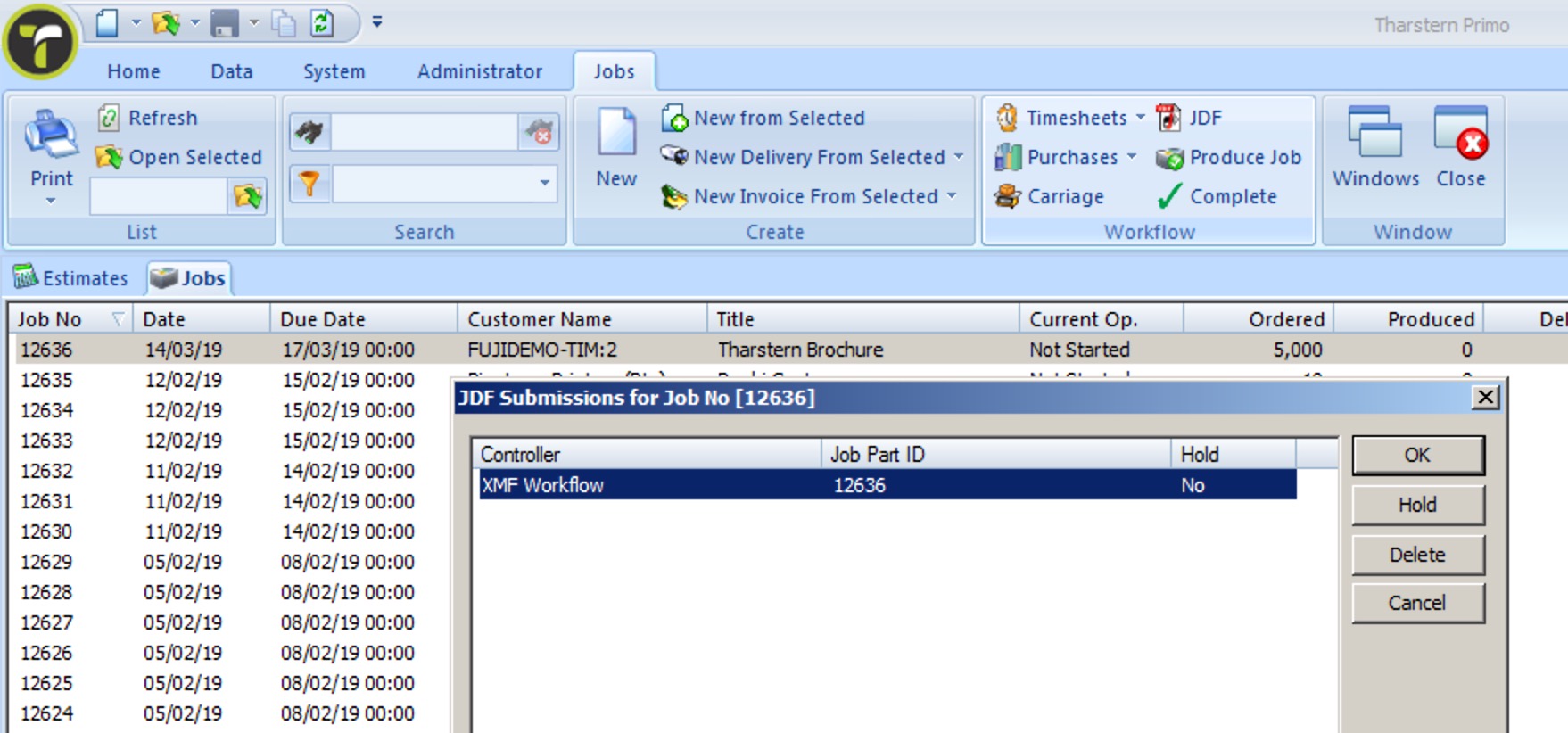

Fujifilm XMF’s integration with Tharstern enables print providers to benefit from advanced automated production direct from the MIS system into the XMF Workflow. A key benefit of this integration is the ability to deliver additional PDF content attached to an MIS job, with the help of automatic page assignment for future reference purposes. This enables print providers to streamline the delivery of artwork throughout the organisation, and allows old jobs to be visible after they have been archived and deleted from within XMF. This is especially beneficial for web-to-print workflows.

A further advantage is that print jobs can be created automatically. Jobs created in the user’s MIS are pushed directly into XMF, including the full job description, customer details, product details and imposition requirements. This saves time and ensures that jobs are created consistently. Moreover, the integration enables users to select XMF job templates based on existing templates, which are picked automatically using criteria within the MIS, saving time and resources.

The integration with EFI Pace allows users to benefit from complete two-way end-to-end workflow integration. EFI Pace is a proven MIS solution exclusively designed for the print industry that enables users to further increase operational efficiencies and maximise profits through process automation. XMF’s messaging to EFI Pace automatically completes all pre-press job plan activities in EFI Pace Scheduling, reducing the time and touches for pre-press data collection. A job can be submitted to XMF directly by EFI, with the jobs then automatically processed in XMF. Once done, XMF sends information about the production timings and the number of plates used back to the MIS and the data is stored. This enables the EFI Pace MIS to automatically not only manage the cost of the job, but also plate utilisation.

John Davies, Workflow Product Group Manager, Fujifilm Graphic Systems Europe, says: “Fujifilm prides itself on partnering with the very best technology providers and developers available, and these new integrations are the latest example of that. We have had the ability to take in print jobs from MIS systems since XMF was first introduced in 2007, but integrating with the Tharstern and EFI Pace MIS systems marks a significant step forward. XMF can now provide customers with the best opportunity to stay ahead of the competition and maximise profit potential, automating processes and giving them full control of the flow of information throughout production.”

For more information on Fujifilm XMF workflow visit: www.fujifilm.eu/eu/products/graphic-systems/print-production-solutions