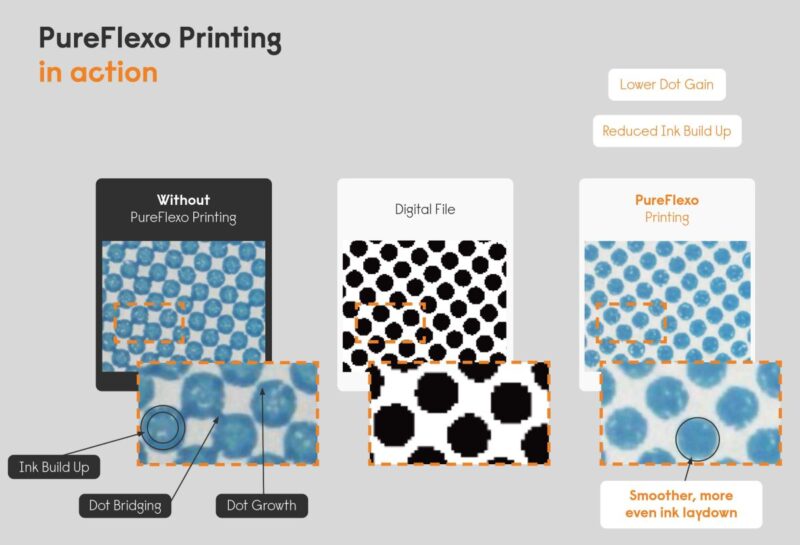

Miraclon, home of KODAK FLEXCEL Solutions, today announces the launch of spot color support for PureFlexo Printing. Introduced in 2021 for process printing, PureFlexo Printing controls unwanted ink spread and allows for greater latitude on press to meet today’s high-quality expectations of brand clients while maximizing plant output and efficiency. It reduces unscheduled press stops and ultimately improves businesses’ financial bottom line. Delivered as a new feature set for the KODAK FLEXCEL NX Print Suite for Flexible Packaging, today’s announcement enables flexible packaging printers to expand the cost-saving benefits of PureFlexo Printing to higher volume anilox applications, and is consistent with Miraclon’s commitment to deliver a constant stream of innovation to customers.

“PureFlexo Printing is enabled by unique multi-functional plate surface patterns designed to precisely control ink flow during printing. The rigorously tested and patented technology set now includes surface patterns with edge effects specifically designed to manage the ink flow characteristics of spot color inks,” says Dr. John Anderson, Director of Advanced Printing Applications at Miraclon. “When higher anilox volumes are used for traditional larger pigment-based spot colors, it usually results in the use of harder tapes, higher impression, and other common printing practices to adjust to the higher anilox volumes. These practices often produce undesirable print effects such as halo, dirty print, and TEV (trailing edge void), while the higher ink volumes also have greater drying needs, causing slowdown in the flexographic printing process to increase drying capacity. PureFlexo Printing addresses all these typical issues to ensure better uptime and consistency on press.”

“Spot color support for PureFlexo Printing is an important addition to any trade shop or converter’s toolset to maximize productivity in the press room,” adds Grant Blewett, Chief Commercial Officer at Miraclon. “As businesses are continuously looking at improving efficiency to increase their financial bottom line while also minimizing their environmental impact, many customers are already experiencing the benefits that PureFlexo Printing delivers. The savings soon add up when the reduction of just one unscheduled press stop per day on a press can deliver up to 60,000 Euro or $65,000 in savings per year. The addition of its use for spot colors will now further support their business growth.”

Spot color support for PureFlexo Printing is included in a subscription to the KODAK FLEXCEL NX Print Suite for Flexible Packaging, a fully integrated platform designed to provide tailored solutions for specific applications, creating greater efficiencies in high quality flexo print, alongside expert assistance, and tools to maximize the benefits for pre-press providers and printers.