With aluminium prices at historic highs and printers seeking to economise where they can, Fujifilm has designed a radical new business process that allows printers to effectively administer or even outsource their plate production. Now, following a successful trial in the UK, Fujifilm’s PLATESENSE initiative is set to revolutionise the pre-press process for printers throughout Europe. Litho printers across the region will now have the option of either reducing overall administration or allowing Fujifilm to help manage the plate production process so that they can concentrate on running their businesses with maximum efficiency.

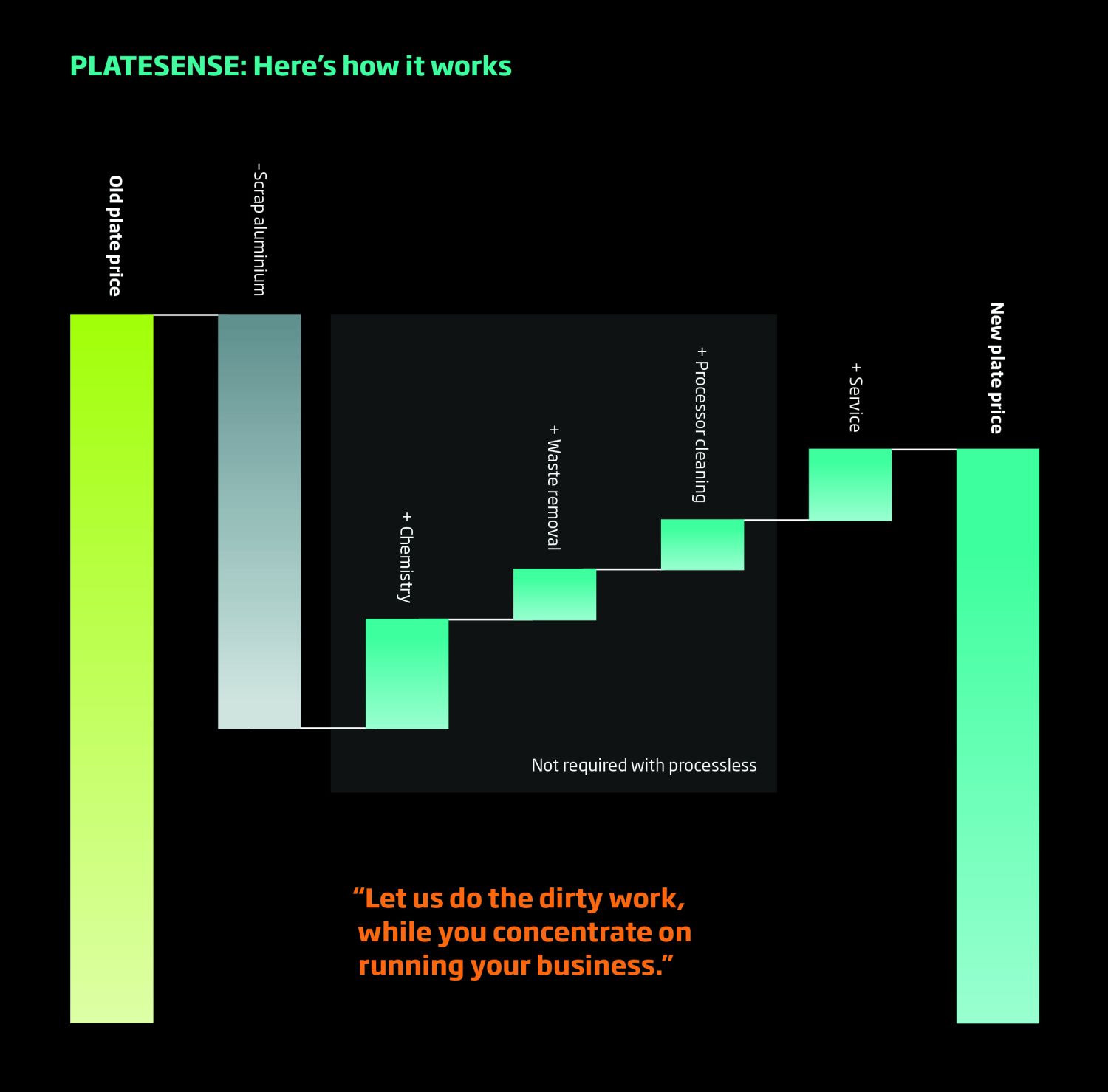

Under this innovative new programme, Fujifilm delivers plates to customers when they need them, along with all associated CTP equipment and consumables, while also managing waste and aluminium collection (helping to protect printers from plate price increases) and providing comprehensive processor maintenance, service and support. Extra services can also be rolled in, including options such as an upgrade to Fujifilm’s industry-leading XMF Workflow solution and even the management of pre-press personnel.

All of this adds up to a simple, all-inclusive plate price which will see operational costs and labour reduced or freed up as Fujifilm helps to take the hassle away from managing the plate production process. This leaves offset printers to concentrate on running their businesses, and allows them to benefit from potential productivity improvements and operational cost savings. The programme offers an invaluable helping hand to boost profitability in a very challenging market.

PLATESENSE is based around Fujifilm’s Superia range of processless and low-chemistry plates, meaning the company can offer a competitive, high quality solution for any application. When considered in combination, not only will printers benefit from the higher performance and consequent resource saving benefits these plates already bring, they will be able to simplify their entire plate production process and reduce operational costs as well.

Chris Broadhurst, Head of Offset Solutions, Fujifilm Graphic Systems EMEA says: “Despite the drive to digital, and the rapid advances in digital print technology which Fujifilm is helping to drive forward, offset print output continues to be much higher than digital output globally. Though this will continue to change over time, the importance of innovation in offset print processes is hugely important. Fujifilm has long had a reputation for helping offset printers boost profitability through the unrivalled performance and durability of its Superia plate range. Our new PLATESENSE programme takes this to another level altogether, introducing an entirely new business model. It has proven its potential, having been successfully trialled in the UK, and having already helped to boost the profitability of a number of businesses in that market. We’re hugely excited now to have the opportunity to deliver the same time and cost savings to new and existing customers throughout Europe, and on a scale they would never have thought possible.”

More information on the PLATESENSE programme can be found at www.platesense.com.