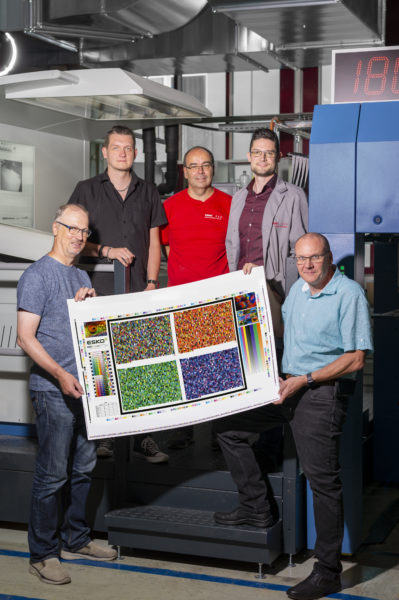

WEXHAM SPRINGS, UK – 25 September 2019 – In a joint project for the Swiss cardboard and paper packaging solution provider PAWI Verpackungen AG, Sun Chemical and leading color software company Esko have successfully implemented seven-color expanded color gamut (ECG) printing at PAWI’s facility in Winterthur. PAWI can now offer customers the option to select ECG printing instead of spot color printing for suitable jobs and take advantage of its significant benefits – a reduced inventory of spot color inks and increased productivity with reduced downtime between jobs (as the seven colors are left in the press), enabling just-in-time production. ECG also offers a number of environmental benefits as energy is saved, less ink is wasted, fewer press wash-ups are needed and transport requirements are reduced.

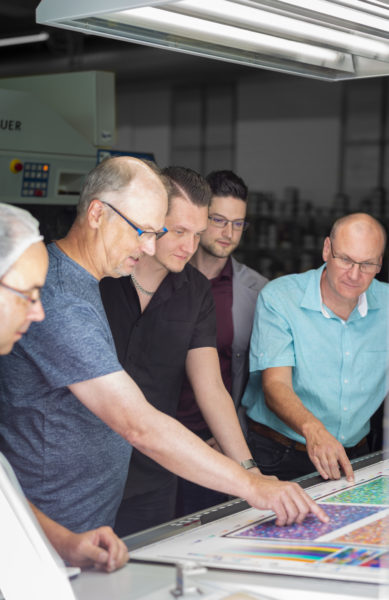

Working in a collaborative three-way partnership, PAWI engaged Sun Chemical, its ink supplier for over 20 years, to set up seven-color ECG printing on a recently acquired eight-color offset press by adding orange, green and violet to the standard cyan, magenta, yellow and black, enabling the reproduction of 95% of spot colors. Sun Chemical achieved this through the deployment of its own ECG solution, SunECG, part of SunColorBox, a unique set of tools and services that enables consistent and accurate digital color communication throughout the entire packaging supply chain. A key component of SunECG is Esko’s color conversion software, Equinox, which identifies the exact percentage of each of the seven colors needed to reproduce the desired spot color. Impressed by the quality of the output produced over an eight week trial, PAWI now plans to offer ECG printing to customers most likely to benefit from it, i.e. customers requiring multiple short runs.

Instrumental to the success of the ECG printing process are Sun Chemical’s robust SunPak FSP inks – some of the most stable running printing inks available on the market. Based on renewable, bio-based materials and designed to work on most folding carton-type, sheet-fed presses including standard, high-speed and wide-format, SunPak FSP addresses the needs of paper and board printers with high quality and sustainable output.

Alexander Honsel, Head of Strategic Projects at PAWI, comments: “While seven-color printing has been around for some time, it is only in recent years that it has really become commercially viable, thanks to the improved stability of the presses and inks and the advances in the software, all supplied by our partners of choice. We’re now looking forward to rolling out the programme in stages and to being able to offer our short-run customers the option to produce high-quality packaging products with seven-color ECG printing at a competitive cost.”

Remo Fehr, Head of Sheetfed Printing at PAWI, says: “Automating the production process from customer to packaging, and in this respect the introduction of seven-color printing, were important steps in our company’s path to expanding industrial production and strengthening PAWI’s position as a leading packaging producer.”

Also commenting on the collaboration, Lukas Mettler, Sales Director Sun Chemical Switzerland says: “PAWI has been a customer of Sun Chemical for over 20 years, so we were delighted when they approached us for help to implement an expanded color gamut printing process. Seven-color printing has become an excellent system to enable printers to fulfil today’s requirements efficiently and we are convinced that this system will help PAWI to meet its customers’ growing demands for more colors and, often in combination, shorter production runs and lead times. Extended color gamut printing is a very valuable tool for rationalizing and streamlining the workflow process and also offers additional environmental benefits.”