As the print market continues its steady trend towards digital, the need to be able to accurately print spot and brand colours on digital presses is becoming ever-more important. Traditionally in offset printing, additional spot colours are used to complement CMYK ink sets in order to more accurately print clearly defined brand colours, something that is not always practical, or even possible, with digital presses.

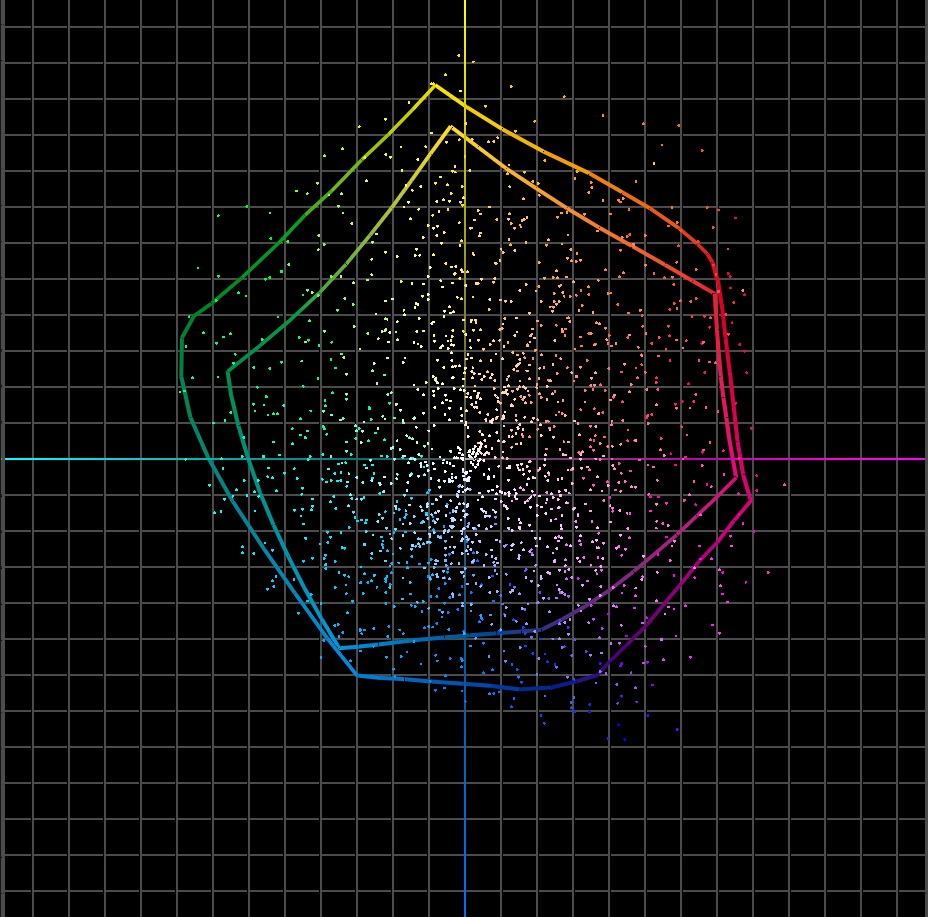

Taking advantage of the very wide colour gamut already offered by the Jet Press, XMF ColorPath Brand Color Optimizer fine tunes the ability to print spot colours and ensures that every spot colour is reproduced as accurately as possible. Brand Color Optimizer can be used to optimise any colour library, including Pantone, HKS and Toyo, to name a few.

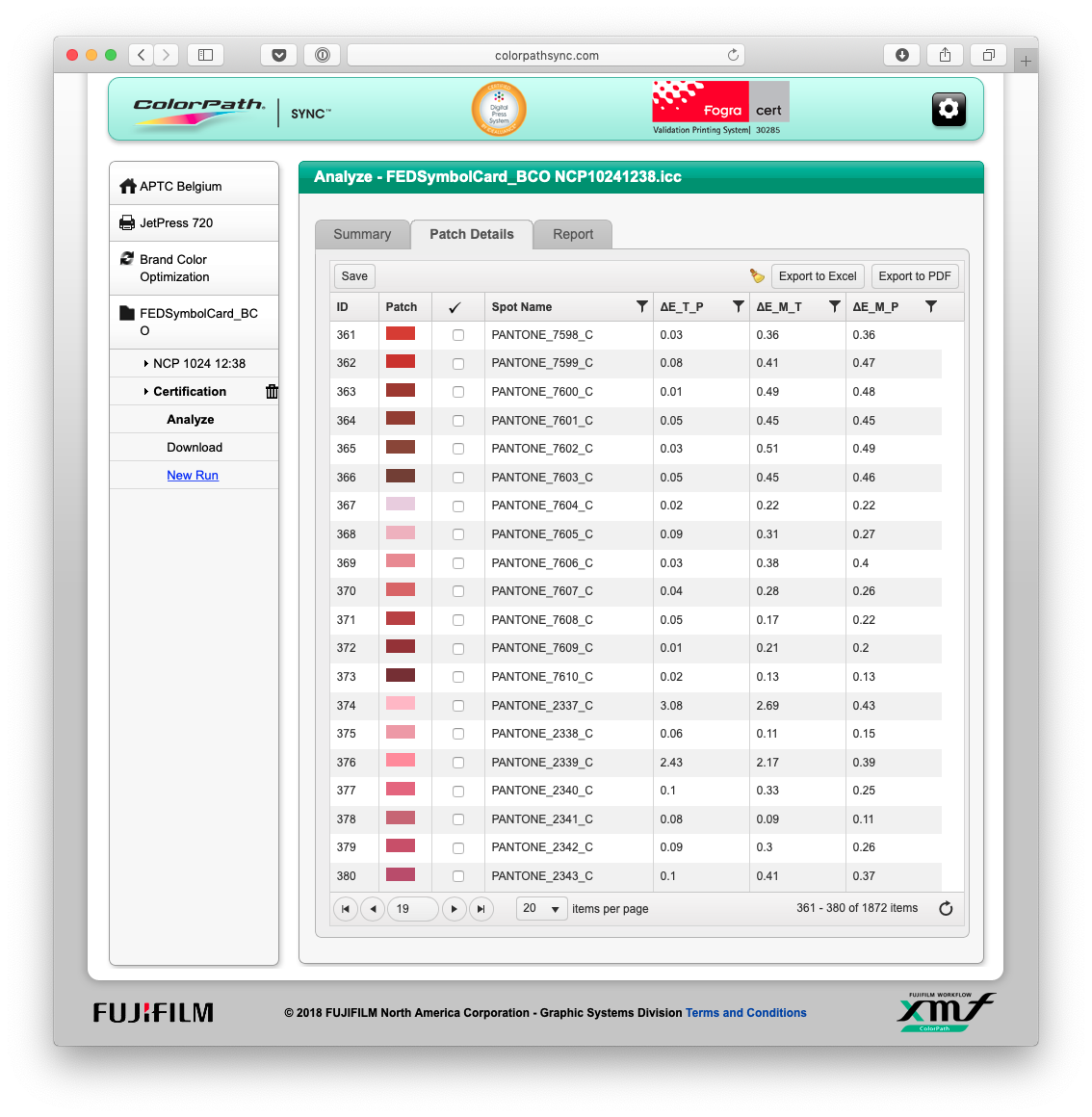

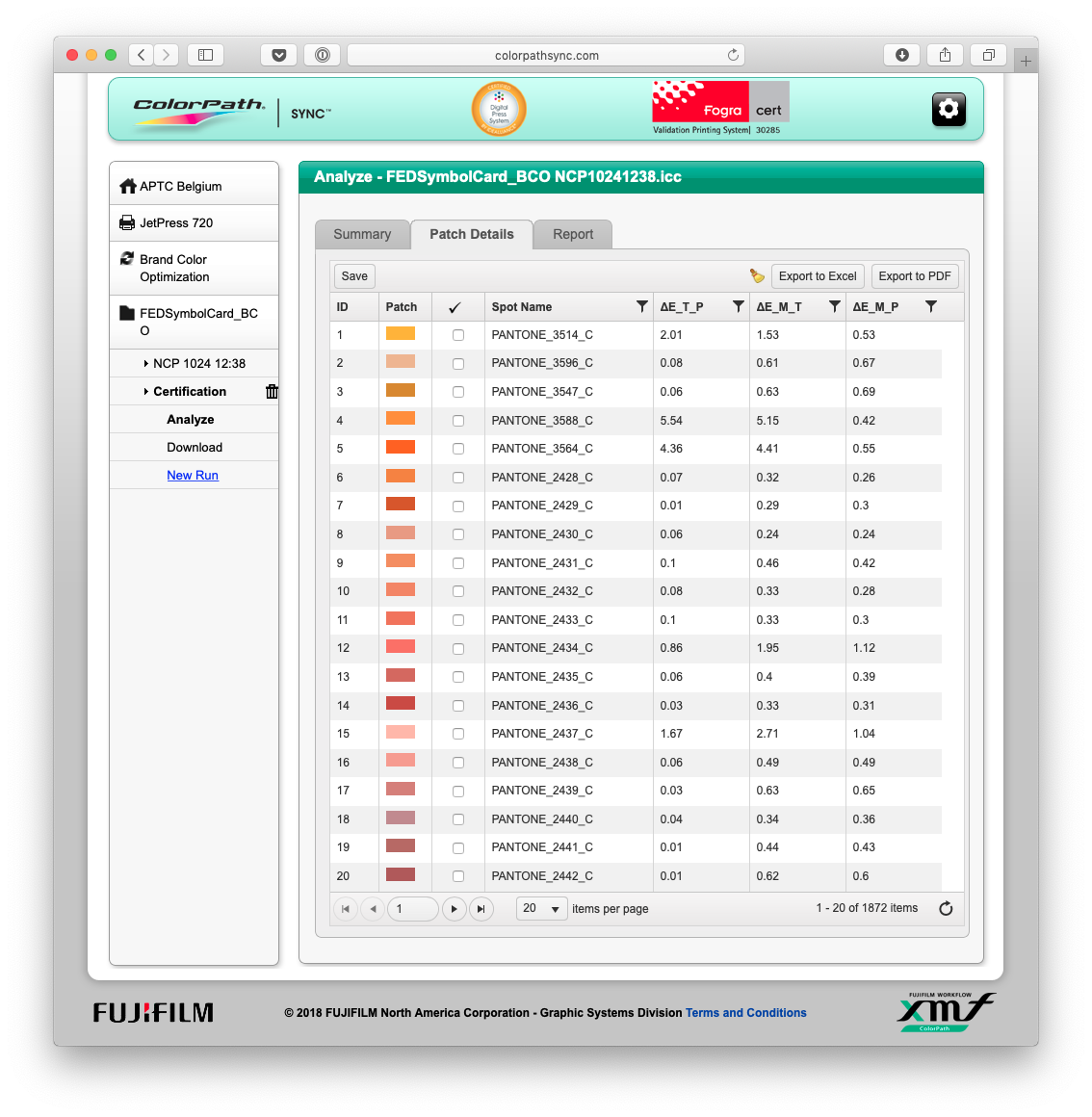

The process of calibration is ultra-fast, with it being possible to calibrate the entire Pantone colour library of 1,872 colours in less than an hour. Brand Color Optimizer does not rely on visual matching or mathematical assumptions, it measures and optimises every single colour within the library.

This now expands the types of colour printing possible on the Jet Press, with the following all now achievable:

- ISO 12647-2 printing

- ISO 12647-2 + spot colour printing

- Wide gamut printing

Because spot colours are managed separately to regular CMYK colours, maintaining ISO printing of CMYK and Pantone spot colours in the same job is easy to manage. In addition, the wide gamut of the Jet Press allows up to 90% of the Pantone library to be accurately printed to a Delta E of less than 3, reducing the expense and logistical complications of purchasing and operating additional ink colours.

Unique to XMF ColorPath Brand Color Optimizer is the ability it provides for users to see, before printing, which press, ink and substrate combination allows the Pantone colours to be accurately printed. In the rare cases that the colour is not achievable, the user is made aware of this without the need to waste valuable time and resources running tests.

“XMF ColorPath Brand Color Optimizer will be especially useful to packaging printers,” says John Davies, Workflow Product Group Manager, Fujifilm Graphic Systems Europe. “But it can be applied to the printing of any brand or spot colours on card or paper across a huge range of substrates. Colour accuracy is hugely important to the world’s biggest brands, and with short run, fast turnaround work on the increase – along with print personalisation and bespoke, targeted campaigns – the need to achieve this level of accuracy on digital presses is more important than ever.”