Fujifilm today announces the European launch of a new low-chemistry plate that only requires a gum clean out, rather than traditional processing chemistry, that outperforms any other in its class. This is because the new Superia LH-S2 plate takes advantage of the same fundamental technologies found in Fujifilm’s leading processless plates to deliver outstanding performance, less waste, and easier handling, and provides the perfect step for printers wanting to move to processless plate production in the future.

As a world leader in the development of high-performance printing plates, Fujifilm has developed an enviable range of industry-leading processless and low-chemistry plate solutions built around the “Superia” concept of resource savings designed to make offset printing more profitable. In particular, the company’s most advanced printing plate, Superia ZD, with longer run lengths and compatibility with UV presses, is bringing the benefits of true processless plate production to many more print businesses.

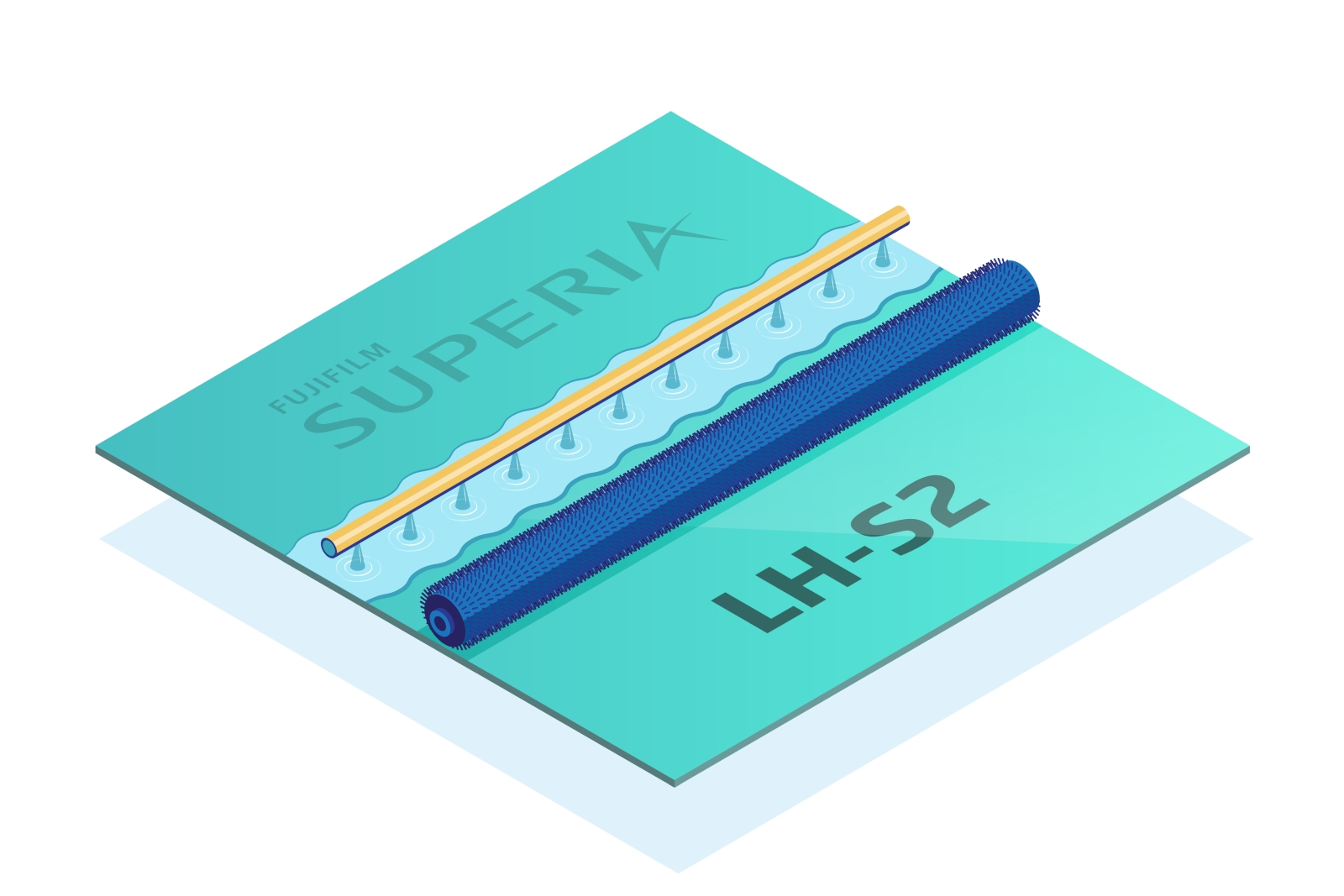

To extend these benefits even further, Fujifilm has used the advanced multi-layer technologies used in the company’s processless solutions to develop a new plate that provides a step to processless. Superia LH-S2 and the company’s processless plates share many of the same core technologies, and have the same fundamental benefits. However, Superia LH-S2 has been designed so that it requires just a simple one-stage clean out with a gum solution, rather than being truly processless, with the benefit being that print businesses can gain many of the advantages or Fujifilm’s processless plate technologies, as a natural step to going processless in the future.

These benefits include:

i) Thanks to its higher sensitivity, Superia LH-S2 is engineered for better productivity. Superia LH-S2 can therefore be used at higher drum speeds helping printers to get maximum productivity and enabling much faster plate remakes.

ii) Eliminating the chemistry used in conventional plate production, Superia LH-S2 plates can deliver outstanding quality at 200 lpi, making them suitable for high-quality print applications, including 20 μm FM screening.

iii) Offering superb toning performance, Superia LH-S2 is robust and built to withstand the rigours of the pressroom. With excellent handling characteristics and resistance to fingerprint marks, press operators can handle plates with confidence.

iv) Superia LH-S2 also offers enhanced ablation performance, meaning that less debris accumulates in the platesetter. Less time spent cleaning the platesetter and replacing filters means more time put to more productive use.

v) The shelf life of Superia LH-S2 is unrivalled, providing excellent consistency from first to last plate, reducing waste and costs.

Says Sean Lane, Offset Product Group Manager at Fujifilm Graphic Systems Europe: “Printers who are considering a move to processless plates, but are not in a position to make such a change immediately, will find Superia LH-S2 the ideal next step down that road. Offering significant environmental and cost savings, and compatible with most platesetters, it offers an ideal route towards Fujifilm’s industry-leading range of processless plates – including Superia ZD and Superia ZP.

“Partnering with Fujifilm for plate production also brings with it a range of other benefits,” Lane continues. “It provides access to our industry-leading inkjet technologies together with our high-performance workflow solutions. This expertise in delivering innovative technology, combined with our world-class support infrastructure, means that we’re perfectly placed to help print businesses to grow and to expand their offering.”