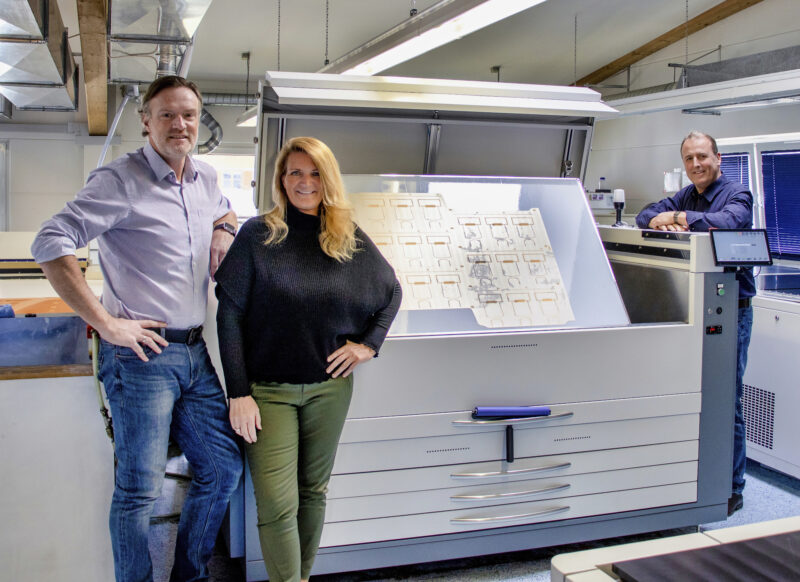

Nägele Digital Repro GmbH, based in Kempten in the far south of Germany at the gateway to the Alps, has expanded its KODAK FLEXCEL Solutions offering by adding a KODAK FLEXCEL NX Ultra Solution from Miraclon to complement the two KODAK FLEXCEL NX Wide Systems it already has in place. As a FLEXCEL NX technology pioneer in Germany, the company has been making plates for highly demanding packaging printing using FLEXCEL NX Solutions since 2010.

Today, FLEXCEL NX accounts for almost 90 percent of all photopolymer plates produced by Nägele. These plates are mainly destined for customers producing flexible packaging for food and cosmetics. For Managing Director Michael Nägele, the investment in FLEXCEL NX Ultra was a logical next step: “By expanding our portfolio with FLEXCEL NX Ultra, we gained a solvent-free alternative for plate processing, allowing our clients the option of a water-processed plate while they can continue enjoying all of the quality and efficiency benefits FLEXCEL NX plate technology is known for.”

According to Nägele, the shorter platemaking time of well under an hour is one of FLEXCEL NX Ultra’s key advantages, and one that makes a big difference for customers: “Speed is always an advantage, of course. That could prove to be a big asset for us in certain situations, for instance if a plate is damaged when it is mounted in the print shop and needs to be replaced immediately.”

Since it builds on the technical infrastructure of the FLEXCEL NX System, Nägele simply had to install the FLEXCEL NX Ultra Processor in order to make FLEXCEL NX Ultra Plates in a VOC-free, water-based washing process. “FLEXCEL NX Ultra helps us reduce our use of solvent, so that we only rarely have to switch on our solvent recovery system, which is very energy-intensive. That takes our production process an important step forward towards a more sustainable footprint,” Nägele explains.

Initial feedback from printers confirms that the FLEXCEL NX Ultra Plates are convincing on press with its excellent ink transfer precision – thanks to the flat top dot technology combined with advanced plate patterning options – and significantly longer runs before the need for plate cleaning. “Added to that, the FLEXCEL NX Ultra Plates provide exceptional registration accuracy”, he says. “In seven-colour ECG printing that’s quintessential.”

Nägele concludes: “In the race to establish FLEXCEL NX Ultra technology in the German market, we were keen to be among the front runners once again. Thanks to Miraclon, it now enables us to take the next step in continuing to drive the transformation of flexo.”

Innovative and reliable partner to packaging printers

Founded in 1975 by Manfred Nägele, who still owns the company to this day, Nägele Digital Repro GmbH has grown over the decades to become a reputed, supra-regional provider of packaging prepress and platemaking services. The family-owned firm, which employs 15 people, sees itself as a partner to packaging printers, primarily catering for clients in southern Germany as well as in neighboring regions in Switzerland and Austria. They are also able to provide printers in Frankfurt, Hamburg and even Poland with sleeves and flexo plates at short notice. Apart from producing photopolymer and elastomer flexo plates and sleeves, Nägele also prepares data for digital packaging printing. The company’s equipment inventory is carefully and strategically planned to ensure the highest levels of supply reliability, with the two FLEXCEL NX Wide Systems likewise part of this strategy.